Road Solar Collector

Black Surfaces Absorb Heat

Black roads can be used to collect solar heat in summer. The temperature on a black road in full sunshine will often be 15°C higher than the air temperature in the shade, at which time the heat radiated up from the road will be as much as the heat being absorbed down from the sun. This temperature can be collected by water circulating through an array of pipes embedded in the surface of the road, allowing continuous collection of heat on hot summer days: generating on site renewable energy.

Heat is in plentiful supply in summer – but is urgently demanded in winter for space heating. This time gap between supply and demand calls for Seasonal Thermal Energy Storage. The gap can readily be bridged by using a thermal bank: the heat from the road can be transferred down to a thermal bank in the ground. This can be achieved using thermoactive foundations or boreholes and will increase the natural temperature of the ground (around 10°C at a depth below six metres in northern Europe) up to over 30°C. The ground only receives heat slowly.

However, the advantage of this is that once heat is absorbed by the ground it will only move away very slowly. The thermal bankit can maintain its warmth through to the winter when it can be readily extracted by a suitably adapted ground source heat pump.

A heat pump has half as much work to do if it starts with warm ground so the Coefficient of Performance can be twice the level expected of an "unassisted GSHP".

This recycling of heat energy from summer to winter through thermal banks is termed Interseasonal Heat Transfer. For a building with a cooling demand in summer and an equivalent heating demand in winter the advantages of ground source cooling and ground source heating are highly complementary: balance can be achieved through using the ground itself for natural thermal energy storage.

Optimisation of Road Solar Collector

Optimisations aim to increase the temperature of the water at the outlet of the collector. The higher the temperature, the higher the efficiency of the total energy system.The work in the last year has focussed on minimising the depth of the pipes in the road without compromising the structural stability of the road.

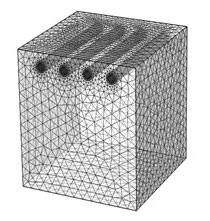

Finite element model of pipes in asphalt and structural tests carried out at Mostostal.

A novel element studied is the application of an epoxy resin layer on top of the road. The effect is that a redistribution of loads occurs, improving the structural behaviour of the road and prolonging its lifespan.

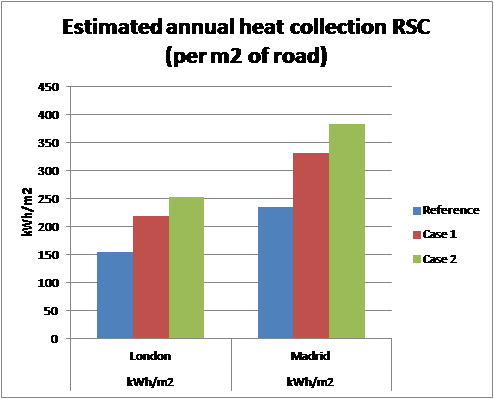

The graph below shows how the annual yield of a road solar collector can be improved by 41% by optimising the lay-out of the piping in the road (compared to the reference case). An improvement of 63% is possible compared to the reference case by further reducing the depth of the pipes from 9 to 5 cm, in combination with a resin layer on top of the road.

Thermal yield for per m² of road:

Reference case;

With pipes in the binding asphalt course; Pipes in wearing course with resin layer on top.

Application of a coating with an emissivity lower than 0.9 will significantly reduce heat losses due to infrared radiation and will therefore provide an additional improvement in the thermal yield of the road solar collector.

A simple thermal model of the road solar collector was made for the assessment of districts. The efficiency curve was determined as a function of parameters such as depth, diameter and lateral spacing of the piping.

Mostostal has carried out structural tests to validate the calculations. However, in the laboratory tests carried out, the adhesion of the top resin layer to the base of the road appeared to be rather poor. Further work is needed before the addition of a resin top layer can be recommended on practical applications.